From Weiler to MAX-truder New standards in modular plant engineering

70 years of engineering expertise

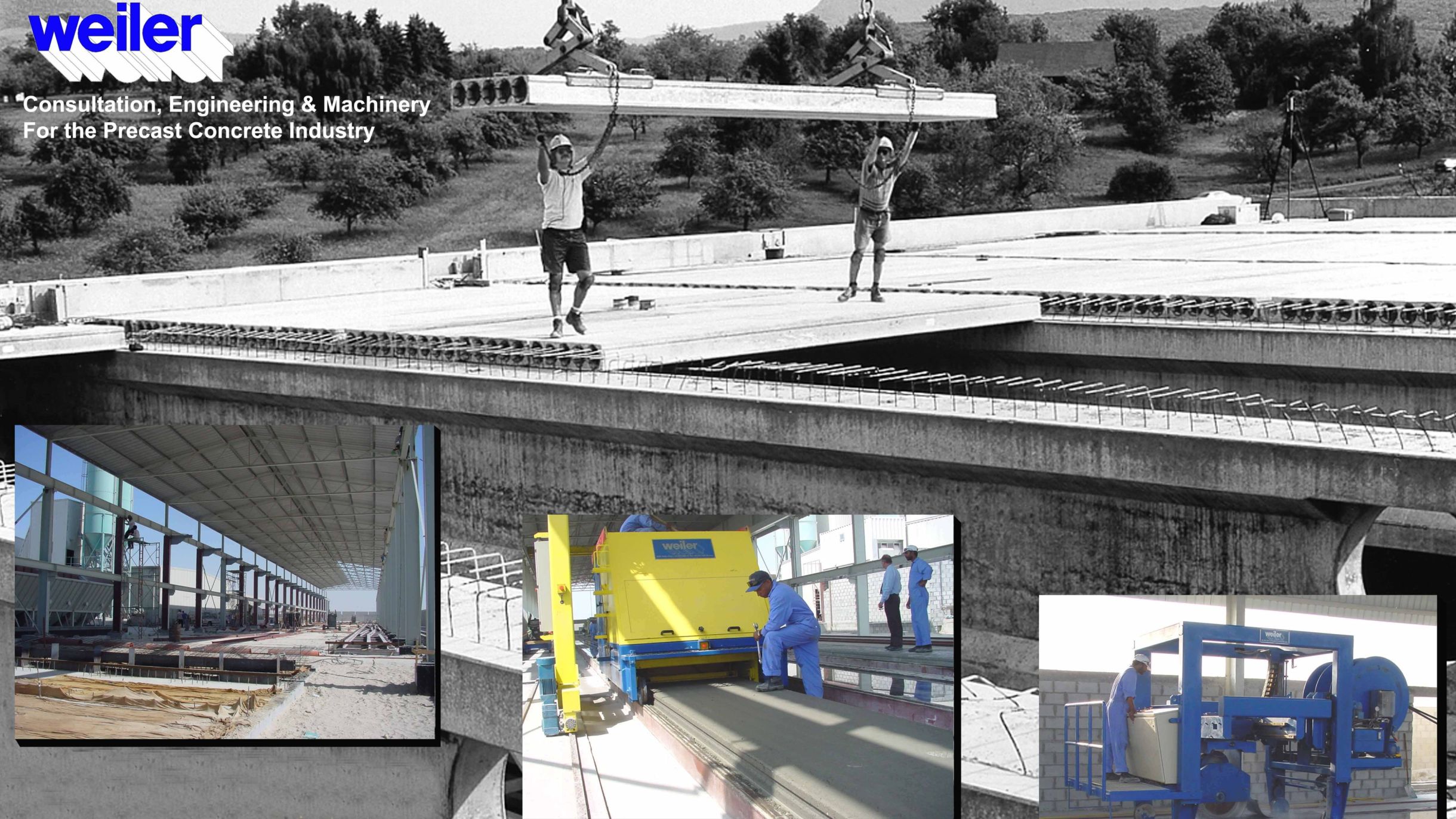

Many professionals in the precast concrete industry know Weiler Maschinenbau or Weiler Precast as a manufacturer of machinery and plants for prestressed and precast concrete production. Since 2017, MAX-truder GmbH has continued this technical tradition of Weiler.

From early on, the company focused on innovation, precision and quality Made in Germany. With plants and machines operating worldwide, it has represented German engineering and reliability for decades.

The guiding idea has remained the same for more than seven decades: producing precast concrete elements more economically, with better resource efficiency and ongoing technological advancement. This vision runs like a common thread through the company’s history – from the first slipformers of the 1950s to today’s modular, digitally controlled production systems from MAX-truder.

From the beginnings to a modern plant manufacturer

Weiler GmbH was founded in 1954 as weiler Brauer KG in Germany and developed over the decades into an internationally recognised supplier of machines and plants for prestressed and precast concrete production. Weiler machinery is still in operation worldwide today, valued for its technical durability, operational safety and consistent performance over many years.

This mindset shaped the company’s development and influenced the entire industry. The plants manufactured by Weiler were in demand worldwide because they were robustly engineered, low maintenance and designed for long-term operation – qualities that remain closely associated with German engineering to this day.

With the reestablishment of the company as MAX-truder GmbH, these values were deliberately carried forward. The team, manufacturing, technical expertise, service locations and high quality standards remained unchanged. What was added were digital control solutions, modular plant concepts and a stronger focus on global interconnectivity. As a result, the company continues to be a reliable partner for the international precast concrete industry.

MAX-truder: modular solutions with Weiler DNA

In 2017, Weiler GmbH became MAX-truder GmbH. The name “MAX” stands for “Modular Application Extent” and describes the key principle behind today’s product philosophy: machines and plants designed in a modular way, capable of growing with customer and market requirements. Each production line can be individually adapted, expanded or modernised depending on the needs and production goals.

Behind this concept lies the conviction that adaptability, efficiency and future readiness are as important today as precision and quality. MAX-truder combines both: the technical experience and manufacturing competence that distinguished Weiler for decades and an openness towards digital technologies and modular system solutions.

MAX-truder therefore not only stands for the continuation of a successful tradition, but also for its consistent further development. The core values – engineering excellence, reliability and quality – remain a central part of our identity. At the same time, the focus is firmly on the future, on plant concepts that are more interconnected, more sustainable and more future-proof than ever before.

Products and technologies

MAX-truder manufactures machines and plants based on the technical foundations developed by Weiler – now equipped with modern control systems, optimised operation and digital networking.

The product portfolio includes:

- Complete precast plants – stationary or mobile, modularly expandable

- Extruders for hollowcore slabs and wall panels

- Slipformers for various prestressed concrete elements

- Prestressing systems with automatic documentation of prestressing operations

- Cleaning systems for production beds

- Formwork systems for stairs, columns, beams and girders

- Tilting tables for horizontal production of wall elements and other panel-shaped precast components

- Service, spare parts and retrofit – maintenance, inspections, original spare parts and modernisation of existing plants.

These systems are in operation worldwide – from Europe to the Middle East, from Asia to South America. Discover our international projects and references in the maxglobal section.

Many precast plants originally built with Weiler machinery are now being modernised or expanded with MAX-truder machines and modules. This ensures system compatibility and provides long-term benefits through technology that grows with the customer.

Continuity and advancement in plant engineering

The foundation has remained the same: technical competence, experience and the ambition to build plants of lasting quality. But the framework conditions have changed. Production processes today are more digital, efficient and interconnected than ever before.

MAX-truder responds with a modular concept: where individual machines once dominated, integrated systems now take centre stage – covering the entire production process, from concrete preparation through manufacturing to automation and process monitoring.

Despite all technological progress, the character of the brand remains unchanged: precise, robust, reliable. Qualities we value and which will continue to form the basis of our approach.

Experience that builds trust

Reliability is not created by words but by consistent action. For decades, we have stood for exactly this reliability – in development, manufacturing and customer support.

Our aim is to foster long-term partnerships and provide technical solutions that operate reliably even after many years. Many of our customers have been with us for several decades.

With a strong focus on service, spare parts availability and technological development, we safeguard the performance of existing plants and the future of new projects. In this way we combine heritage with progress – for precast production that is built on experience and aligned with the future.